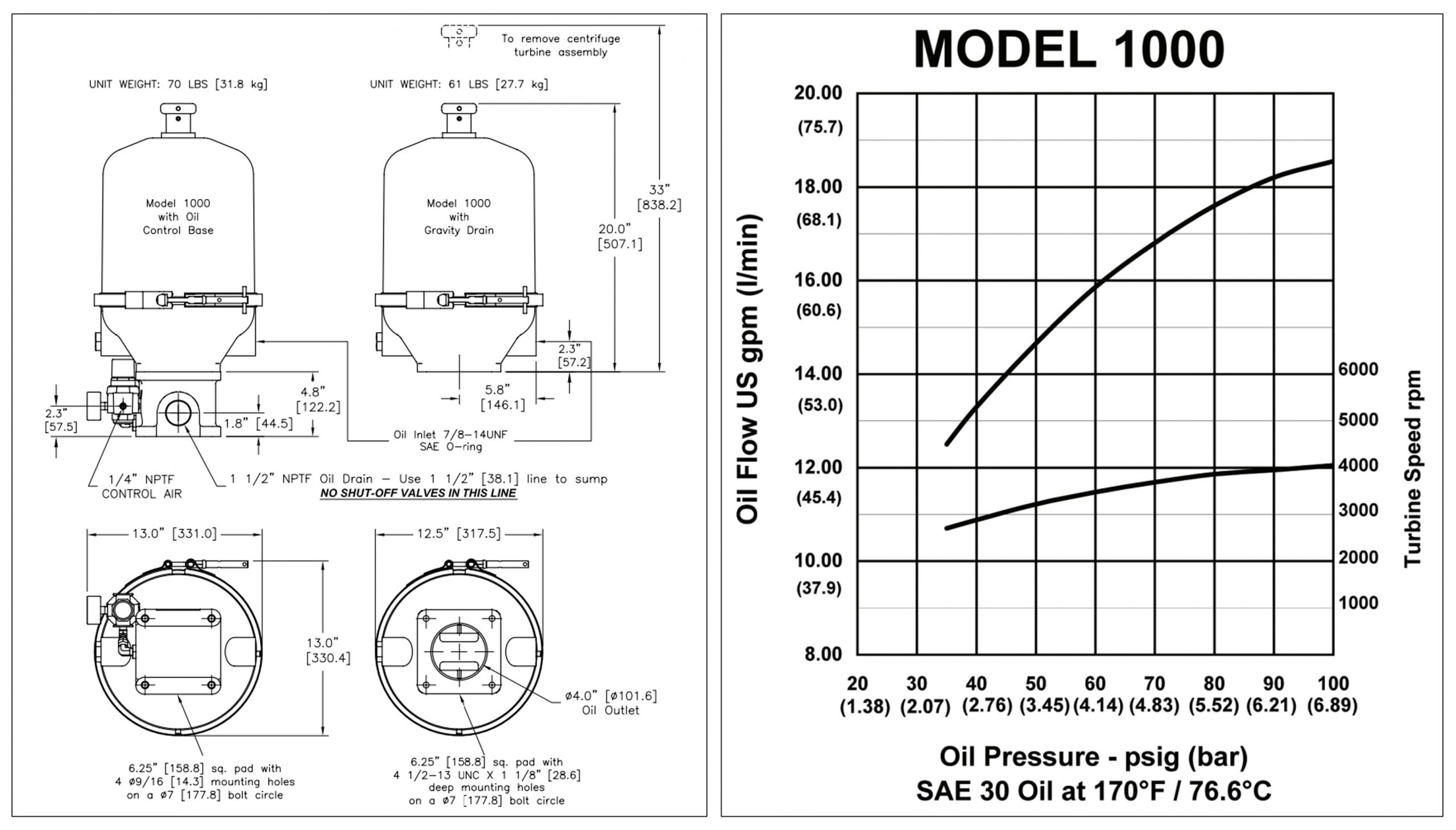

Model 1000

Oil Centrifuges

- Throughput: 8, 12, & 16 Gallons per minute (30, 45, 60 L/min)

- Oil Sump Capacity: 120, 180, or 240 Gallons (454, 681, 908 L)

- Dirt Holding Capacity: 350 in3 (5462 cm3)

- Also Featuring: : Bottom drain, Optional oil control base

- True centrifuge

- Reduces hazardous waste

- Reduces engine wear

- Extends oil and filter life

- Removes solids below one micron

- Diagnostic tool

- User friendly

- Easy installation

- Rugged construction

Oil Supply to Centrifuge

Oil supply should be taken from a source as close to the lube oil pump discharge as possible and on the dirty side of the full flow oil filter. A 3/4” NPT pipe or #12 hose supply should be used for supply with a full-opening ball valve installed in supply line to allow the centrifuge to be isolated for cleaning without shutting the engine down. The centrifuge will operate efficiently at 30 to 90 psig with the preferred pressure of 60 to 80 psig. Below 30 psig, an internal idle cutout valve will close to prevent low oil pressure during low engine RPM.

Helpful Links

Description

Oil Supply to Centrifuge

Oil supply should be taken from a source as close to the lube oil pump discharge as possible and on the dirty side of the full flow oil filter. A 3/4” NPT pipe or #12 hose supply should be used for supply with a full-opening ball valve installed in supply line to allow the centrifuge to be isolated for cleaning without shutting the engine down. The centrifuge will operate efficiently at 30 to 90 psig with the preferred pressure of 60 to 80 psig. Below 30 psig, an internal idle cutout valve will close to prevent low oil pressure during low engine RPM.

Clean Oil Return to Sump

The oil drain line should be free of any shut-off valves.

Using Oil Control Base (OCB) Preferred

The oil control base, Part # COCB-01 permits the Model 1000 centrifuge to be installed in any convenient location

near the engine.

The clean oil drain line to the sump should be a 1- 1/2” minimum diameter, unrestricted hose or pipe. A 1-1/2” connection located above the oil level is preferred. Alternate oil fill openings or drilled-and-tapped holes in crankcase doors are options that can be used. A below oil-level-return will require the use of a 1 1/2” check valve, Part # C300-24, located at the OCB oil outlet connection to prevent back-flow when the centrifuge is being serviced.

Only low pressure drop check valves are permitted in the drain line, manual shut-off valves should never be used on the drain line. The OCB controls the oil flow from the centrifuge back to the engine and insures the centrifuge reaches maximum speed and efficiency. To accomplish this, the OCB uses a very small volume of compressed air; approximately 0.02 SCFM. The OCB is capable of receiving compressed air from any 5 to 25 psig source. If there is no compressed air available it may be possible to use turbocharger air or air from a positive displacement blower. Instructions for this type installation are available from your SPIN-CLEAN™ representative.

Using Gravity Drain Engine Mounting Only

For gravity drain without the OCB, the SPIN-CLEAN™ centrifuge must be close-coupled to the engine sump using an unrestricted 4” I.D. drain back into the engine above the engine normal oil level. A crankcase door, inspection cover, etc. can be modified to provide a suitable oil return back into the engine. The drain is correct if you can drop in a 4” diameter ball and it can freely roll through the drain line into the engine.

Mounting Considerations

SPINCLEAN™ Centrifuges are high-speed devices and should be securely mounted to prevent excessive vibration. Model 1000 may be installed up to 15 degrees from vertical.